Home | News › XXL Monopiles vibrated into Cuxhaven (German) soil

Ramming causes harm to people and sea life.

In the test area, parts of the foundation of the windmill -the so called monopole- is vibrated into the ground. Till now the monopiles were rammed into the ground by means of an impact hammer, which takes a long time and takes a lot of efforts to do. Furthermore it causes a tremendous noise which harms people and sealife. Especially sea life in the Northern- and Eastern Sea are very sensitive for noise and under the water the noise is spreaded and strengthened even more.

‘With a soft touch we are vibrating the pile into the ground’

At the moment we are vibrating the monopiles into the ground, It is less complicated and therefore saves costs. When ramming a monopile into the ground with an impact hammer, it takes a lot more efforts in order to decrease the noise.

When we use the vibratory equipment, we reduce the initial noise emission tremendously, we are much faster and we save on additional hours, efforts- and equipment, says Tobias Griesshaber from RWE Innogy.

The vibrating is less harmful for mankind, the animals, and the monopile itself. Experts believe that this kind of new technical development can extend the life of the current 20 to 25 years. ‘Every hammer blow makes the monopile 1 week older, says Mr. Griesshaber from RWE’. By vibrating the monopole, the pile is treated with a soft touch and regular energy. This causes the ground to a temporarily liquefaction and the soil resistance reduced dramatically. The 93 ton monopile was vibrated into the ground within a few minutes. The hydraulic impact hammer method costs at least 1 hour to get the monopile into the ground.

The tests must bring proof in stability

The experts have high expectations with regards to the vibrating method. It is clear it saves time that has been proven already. Now they have to prove, if vibrated monopiles have as much lateral stability as hammered monopiles.

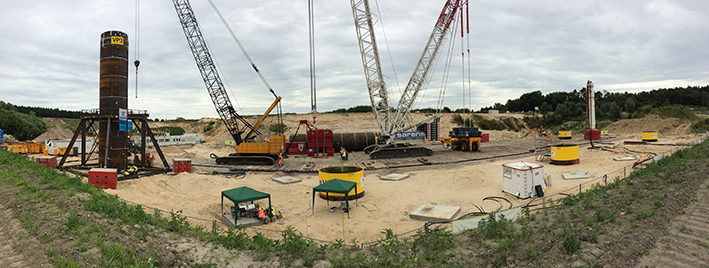

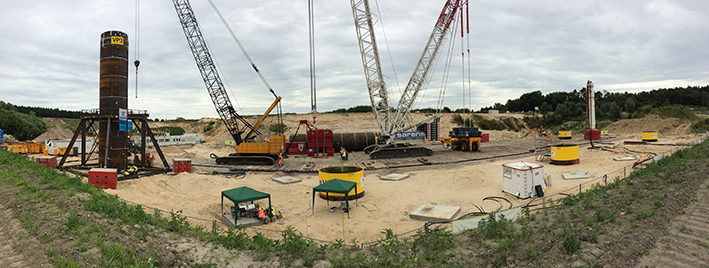

Because of this a total of 6 monopiles are driven into the ground of the testpit; 3 monopiles are vibrated and 3 monopiles are hammered into the ground. ‘We will announce the winner’, says the site manager Ralf Sternberg.

The total costs of the test are over six million euros. When the new vibration technology emerges as the "winner", the return on investment is a simple one. When the vibrating method breaks through we can expect it to be in operation early next year.

Some external links to information:

This article is a translation of the German article at the NDR website.

XXL Monopiles vibrated into Cuxhaven (German) soil

At the test site of RWE in Cuxhaven a 93 ton steel monopile which disappears into the ground in seconds. The offshore industry is testing a new art of constructing a wind farm, which test is essential for the industry.

Should it live up to the expectations it can lead up to in saving millions of money for the offshore industry and protect sea life and people?

Ramming causes harm to people and sea life.

In the test area, parts of the foundation of the windmill -the so called monopole- is vibrated into the ground. Till now the monopiles were rammed into the ground by means of an impact hammer, which takes a long time and takes a lot of efforts to do. Furthermore it causes a tremendous noise which harms people and sealife. Especially sea life in the Northern- and Eastern Sea are very sensitive for noise and under the water the noise is spreaded and strengthened even more.

‘With a soft touch we are vibrating the pile into the ground’

At the moment we are vibrating the monopiles into the ground, It is less complicated and therefore saves costs. When ramming a monopile into the ground with an impact hammer, it takes a lot more efforts in order to decrease the noise.

When we use the vibratory equipment, we reduce the initial noise emission tremendously, we are much faster and we save on additional hours, efforts- and equipment, says Tobias Griesshaber from RWE Innogy.

The vibrating is less harmful for mankind, the animals, and the monopile itself. Experts believe that this kind of new technical development can extend the life of the current 20 to 25 years. ‘Every hammer blow makes the monopile 1 week older, says Mr. Griesshaber from RWE’. By vibrating the monopole, the pile is treated with a soft touch and regular energy. This causes the ground to a temporarily liquefaction and the soil resistance reduced dramatically. The 93 ton monopile was vibrated into the ground within a few minutes. The hydraulic impact hammer method costs at least 1 hour to get the monopile into the ground.

The tests must bring proof in stability

The experts have high expectations with regards to the vibrating method. It is clear it saves time that has been proven already. Now they have to prove, if vibrated monopiles have as much lateral stability as hammered monopiles.

Because of this a total of 6 monopiles are driven into the ground of the testpit; 3 monopiles are vibrated and 3 monopiles are hammered into the ground. ‘We will announce the winner’, says the site manager Ralf Sternberg.

The total costs of the test are over six million euros. When the new vibration technology emerges as the "winner", the return on investment is a simple one. When the vibrating method breaks through we can expect it to be in operation early next year.

Some external links to information:

- OffshoreWIND.biz website: Bilfinger Demonstrates Vibration Piling Procedure

- RWE: an impressive movie of the test with starting-points and higlights. see youtube

- NDR (Norddeutsche Rundfunk): published a video-report on their website

- Cuxhavener Nachrichten published a video-report at youtube (German language)

- ZDF: the Vibro project was briefly on the German TV channel ZDF. You can see it in ZDFmediathek at ~27:00 minutes

This article is a translation of the German article at the NDR website.